Hot Air Circulating Oven Introduction

Hot air circulating oven is a general type of drying equipment which enjoys wide popularity in food and medicine industry so as to keep them easy to store and authentic taste. Actually, the dried food has had quite a long history in China and the drying method has undergone various forms from the original solarization, natural air drying to the hot air food dryer which is totally a great progress in food service industry. Our CT-C series hot air dryer machine has adopted low noise and high temperature-resistant axial flow fan to dry food in a completely closed system, with the thermal efficiency of 35-45%, or even 50%.

Noteworthy Features of Hot Air Dryer Machine

▶ Circulation is processed inside the oven, thus high efficient and energy-saving.

▶ Equipped with adjustable air distributing plates to balance temperature.

▶ Optional heat sources such as hot air, hot water, electricity and far infrared.

▶ Low noise, stable drying and circulating;

▶ Automatic temperature-controlling, easy to install and maintain.

▶ Universal use and wide application to offer people fresh and good tasty food. Dried food? Who is Mouthwatering!

Take a look at the snack district when you go shopping at the supermarket, store or any shopping mall, are you mouthwatering at the pleasant and freshly bagged refreshments? What about the candied fruits? You bet! These dried snacks are exactly attractions to little kids. Actually, dehydrating food is easy and fun. Our air dry oven will help create the pleasant, fruity smells for your sweet homes.

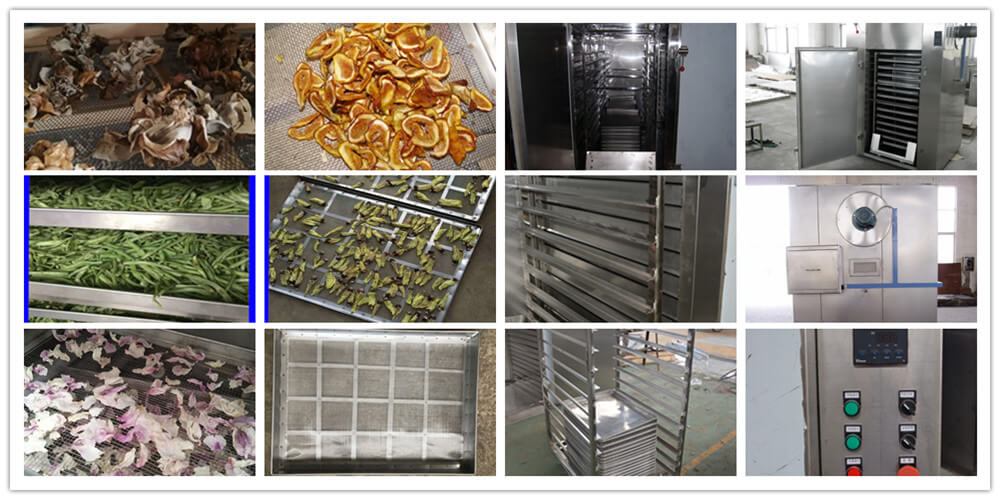

Hot Air Food Dryer Applications

Raw material drying and dehydration technology have been a necessary step in a myriad of fields, either light or heavy industry, especially in the food processing industry. Our industrial drying oven can be typically used for drying the following materials such as Chinese herbal pieces, powder medicines, fruits and vegetables, sausage, aquatic products, plastic resin, and electronic elements, etc.

Hot Air Circulating Oven Technical Data

| Specification | Drying capacity (kg/batch) |

Power (kW) |

Steam consumed (kg/h) |

Heat radiation area (m²) | Air capacity (m³/h) |

Temperature difference allowed (℃) |

Accompanging baking plate (set) | Dimension (L*W*H)mm | Accompanging baking cart (set) |

| CT-I | 100 | 1.1 | 20 | 20 | 1400 | ±2 | 48 | 2430*1200*2375 | 2 |

| CT-II | 200 | 1.1 | 40 | 40 | 5200 | ±2 | 96 | 2430*2200*2433 | 4 |

| CT-III | 300 | 2.2 | 60 | 80 | 9800 | ±2 | 144 | 3430*2200*2620 | 6 |

| CT-IV | 400 | 2.2 | 80 | 100 | 9800 | ±2 | 192 | 4380*2200*2620 | 8 |

| CT-C-0 | 25 | 0.45 | 5 | 5 | 3400 | 0 | 16 | 1550*1000*2044 | 0 |

| CT-C-IA | 50 | 0.45 | 10 | 10 | 3400 | ±2 | 24 | 1400*1200*2000 | 1 |

| CT-C-I | 100 | 0.45 | 18 | 20 | 3450 | ±2 | 48 | 2300*1200*2000 | 2 |

| CT-C-II | 200 | 0.9 | 36 | 40 | 6900 | ±2 | 96 | 2300*2200*2000 | 4 |

| CT-C-III | 300 | 1.35 | 54 | 80 | 10350 | ±2 | 144 | 3300*2200*2000 | 6 |

| CT-C-IV | 400 | 1.8 | 72 | 100 | 13800 | ±2 | 192 | 4460*2200*2290 | 8 |

| CT-C-IB | 120 | 0.9 | 20 | 25 | 6900 | ±1 | 48 | 1460*2160*2250 | 2 |

| CT-C-IS | Special baking bottle | 2.2 | 60 | 100 | 6900 | ±2 | 1140*6160*3240 | 6 | |

| The baking oven which is high efficiency and high temperature far infrared bacterium reducing | 1200*1000*1600 | 1 | |||||||