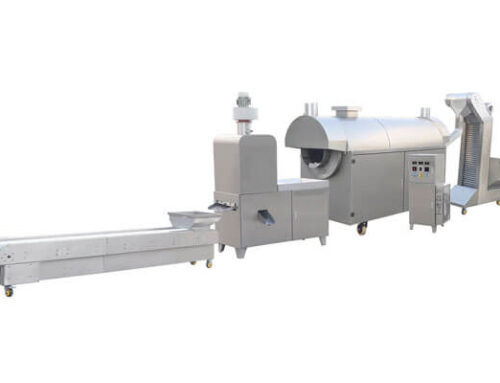

The Introduction of DCLS Series Roasting Line

The DCLS series electromagnetic roasting production line is featured with a high degree of automation, fast speed, high output, and low power consumption. Only one person can operate the whole operation process, which is time-saving, and labor-saving! It is an ideal fully automatic roasting equipment unit in the roasting market today.

Application of DCLS Series Roasting Line

- Oil extraction industry: sesame, rapeseed, flaxseed

- Chemical industry: drying and heating chemical raw materials

- Feed processing industry: roasting raw materials

- Tobacco Processing Industry: Tobacco Processing

- Coarse grain processing industry: rice, millet, wheat

- Condiment industry: chili, pepper, fennel, cumin

- Pharmaceutical industry: Chinese medicine roasting

- Drink industry: Tartary buckwheat (puffed), barley malt

Main Features of DCLS Series Roasting Equipment Unit

-

The high degree of automation

The roasting unit is an assembly line, featured with high speed and high output, and only one person is needed to operate the process.

-

Smart

The machine has a powerful temperature intelligent repair function, strong controllability, and intelligent temperature control.

-

Environmental protection

This roasting line adopts electromagnetic heating and has zero carbon emission to the working environment.

-

Low consumption

The roasting line uses a composite pot body to protect the heat from being dissipated outward, and the thermal efficiency can reach more than 95%, which can save more than 45% electricity than traditional electric roasting equipment.

-

Sophisticated materials

Stainless steel materials are used to ensure the hygiene and safety of baked products, in line with GMP standards.

-

Man-machine interface

Humanized design, intelligent control, the parameter setting is convenient and fast.

-

Fault self-diagnosis function

The fault display is clear at a glance.

Technical Data of DCLS Series Roasting Line

| Model | DCLS 5-40 | DCLS 7-60 | DCLS 7-80 | DCLS 9-100 |

| Capacity | 100-250kg/h | 150-400kg/h | 200-500kg/h | 400-800kg/h |

| Power | 7-56kw | 10-80kw | 15-120kw | 22-180kw |

| Motor power | 1.5kw | 2.2kw | 3kw | 4kw |

| Voltage | 380v | 380v | 380v | 380v |

| Dimension(mm) | 4500*890*1500 | 6500*1010*1600 | 8500*1010*1600 | 10500*1200*1940 |

| Drum size (mm) | 500*4000 | 700*6000 | 700*8000 | 900*10000 |