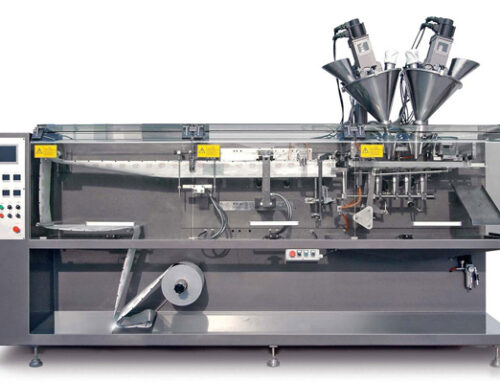

Vacuum Packaging Machine Introduction

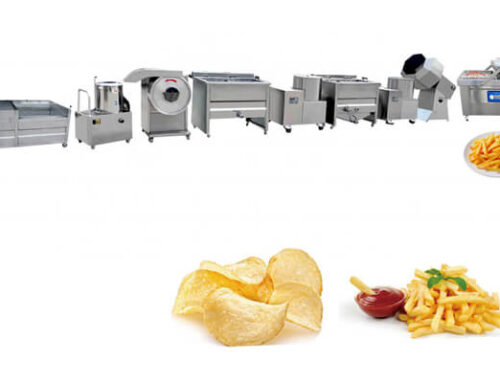

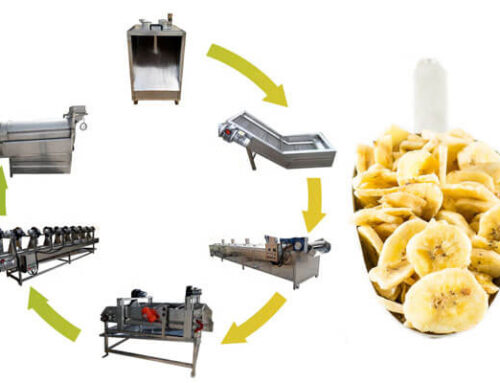

Vacuum packaging machine is integrated the evacuating the internal air, and sealing the package bag so as to isolate the oxygen and fill in the nitrogen, to keep it fresh, to prevent the damp, mildew, rust, worm, pollution or etc. and effectively extend shelf live and freshness date, and in order to be easy to store and transport. It can widely use nylon bag, PP, PC, PVC, HDPE, PS materials to pack potato chips, French fries, banana chips and so on.

Potato Chips Packing Machine Characteristics

1. Double chambers to alternatively operate for high working efficiency.

2. The stainless steel material guarantees higher anti-corrosion rate, longer service life.

3. Easy operation, the four connecting-rod and removable foot wheel will make the operation convenience and energy saving.

4. Diversified capacity and models for customizing choice.

5. It can seal the bags, print the shelf life, leave factory date, serial number and other denotations of the products, in order to match relative regulation of the national food health law.

Working process of Commercial Vacuum Packaging Machine

1. Close the cover first, and the vacuum pump starts to extract air from the up working chamber.

2. Open pressure value and gasbag starts to puff while reaching the predetermined vacuum quantities.

3. Put the press batten compress the seal place, at the same time electrify and heat up.

4. Open the deflation value, after the package bag is sealed over. And then it will deflate automatically

5. Open the cover and take the package bag filled with food and so on.

Technical Data of Vacuum Packaging Machine

| Model | DZ400-2S | DZ500-2S | DZ600-2S |

| Power | 1kw/380v/220v | 2kw/380v/220v | 2.2kw/380v/220v |

| Weight | 180kg | 230kg | 320kg |

| Dimensions | 1050*650*855mm | 1220*680*900mm | 1425*720*950mm |

| Capacity | 60-160times/h | 90-360times/h | 90-360times/h |

| Sealing size | 400*10/2mm | 500*10/2mm | 600*10/2mm |