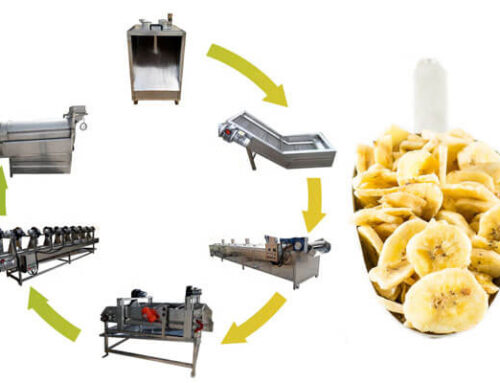

This banana chips line is suitable for the small-scale banana chips production: 30kg/h, 60kg/h, and 150 kg/h.

Main Processing Machines in Small Banana Chips Plant

| Banana Peeling Machine | Remove the peel of bananas |

| Banana slicing machine | Cut banana into pieces |

| Banana chips blanching machine | Blanch bananas and keep the color of the banana chips |

| De-watering machine | Remove the water from the banana chips |

| Banana chips Frying machine | Fry the chips and get crispy chips |

| De-oiling machine | Remove the extra oil from the banana chips |

| Flavoring machine | Season the fried chips, the flavor depends on you |

| Packing machine | Pack the banana chips into plastic bags |

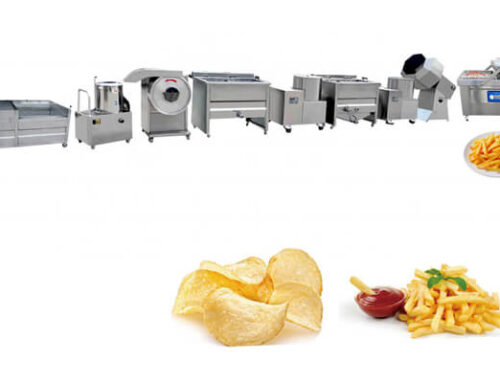

Features of Small Scale Banana Chips Production Line

1. The whole banana chips line is made of stainless steel, long working life.

2. The banana chips line can process banana and plantain into packed fried banana chips.

3. The banana chips plant can also be adjusted to produce potato chips and French fries.

4. Stable running, good performance, simple operation.

Technical Data of 30Kg/hr Small Banana Chips Plant

| No. | Model | Item Name | Power | Weight | Size |

| 1 | IFC300 | Banana Slicing Machine | 0.75kw/380V | 90kg | 540*820*1060mm |

| 2 | PT1000 | Blanching Machine | 15kw/380V | 50kg | 1310*650*700mm |

| 3 | TS500 | De-watering Machine | 0.75kw/380V | 400kg | 940*560*830mm |

| 4 | DYZ1000 | Frying Machine | 21kw/380V | 120kg | 1380*620*950mm |

| 5 | TY500 | De-oiling Machine | 0.75kw/380V | 400kg | 940*560*830mm |

| 6 | BL800 | Flavoring Machine | 0.75kw/220V | 90kg | 1000*800*1380mm |

| 7 | ICP400-2S | Vacuum and Nitrogen Packing Machine | 1kw/380V | 80kg | 540*520*920mm |