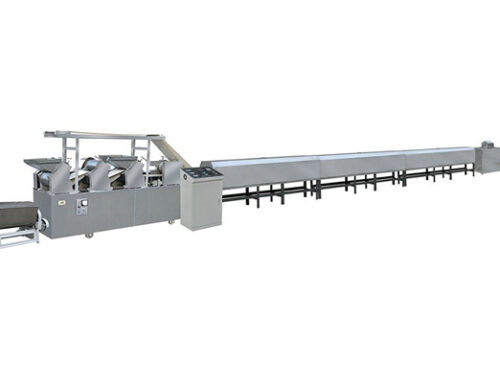

Continuous Potato Chips Dewatering & Deoiling Machine

Potato chips dryer & deoiler machine adopts multiple high-pressure fans to remove the surface water of blanched potato chips and also can be used to separate the oil from fried potato chips. The wind adopts normal temperature, effectively protecting the color and quality of the potato chips. The potato drying machine is also used for removing the excess oil of fried potato chips. The oil removed is collected by drip pan. Potato chips deoiling machine is suitable for continuous operation. The air-dried or deoiled potato chips enter the next process continuously.

Technical Parameters

| Model | FG4000 | FG5000 | FG6000 |

| Power | 6.75 kW | 8.25 kW | 9.75 kW |

| Capacity | 1000 kg/h | 2000 kg/h | 3000 kg/h |

| Weight | 400 kg | 500 kg | 600 kg |

| Dimension(mm) | 4000*1000*1600 | 5000*1000*1600 | 6000*1000*1600 |

Features

1. Potato drying machine is mainly made of high-quality stainless steel, hygiene and durable to use.

2. Easy operation, convenient maintenance, low power consumption, stable performance, high efficiency, low noise.

3. The conveying speed of the mesh belt can be adjusted to meet the requirement of the products.

4. The length and turnings of the oil removing machine can be customized according to the capacity.

5. The height of the fan can be adjusted for different products.

6. Multiple turnings design with airflow reversing device ensures good drying effect.

7. Stainless steel mesh enclosure prevents the small materials from blowing away. The mesh enclosure can be dismounted, convenient for cleaning.

Wide Applications

1. Potato chips dryer machine is mainly used for cooling and drying of washed or blanched fruits and vegetables, as well as sterilized flexible packaging meat products, bean products, and vegetable products.

2. Potato chips oil removing machine is suitable for deoiling and cooling of various fried foods such as meat, fish and bean products.

Working Principle

By the mesh belt, the materials enter the machine from the feed end and move forward at a constant speed. The high-pressure airflow produced by the fans is jetted from the tuyere onto the materials. The tuyere is of air knife shape, effectively increasing the air volume and pressure, making the surface water evaporate at short notice.

The mesh belt has several sections and there is the height difference between them. By utilizing the height difference, the materials are turned automatically, so that the other side can be blown, ensuring the drying effect. The turning also has the function of draining the excess surface water.

Operation

1. Turn on the main power switch, start the blower, start the mesh belt.

2. Put the potato chips uniformly and smoothly on the feed end of the mesh belt. Adjust the conveying speed according to the drying time.

3. Please increase the height of the fan if the height of the materials is higher than that of the tuyere.

4. Please ensure the rotation direction of the motor is correct.

5. If the belt vibrates intensively because of the uneven materials, turn off the power switch immediately and reput the materials.