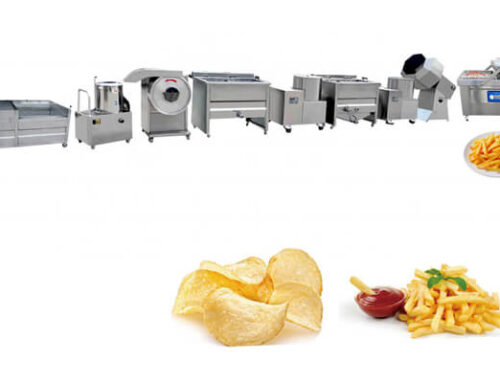

Compound Oil-fried Potato Chips Production Line Introduction

Fully automatic compound oil-fried potato chips production line uses potato whole powder as raw material to produce the compound potato chips. Through the process of mixing, conveying, pressing, form rolling, frying, seasoning and packaging, the raw material is processed into compound potato chips of uniform thickness and uniform appearance. Because the shape of the fried potato chips is the same, the packaging of the chips mostly adopts high-grade packaging in the form of paper cans, which reduces the packaging volume and makes it easy to carry.

Process Steps of Compound Potato Chips Production Line

The compound oil-fried potato chips processing line is in the form of a fully automatic line to save time and effort to produce delicious potato chips. Fried potato chips processing process includes: material mixing, conveying, quantitative feeding, pressing, forming, scrap recycle mixing, frying, seasoning, cooling, and packaging.

1. Raw material mixing

The preparation of raw materials for the production of compound potato chips mainly uses adding a certain amount of ingredients to change the characteristics of the main raw materials to meet the requirements of the process and product performance. Dry mixing and liquid mixing are prepared in advance and then mixed twice. In the preparation of dry mixing and liquid mixing, the ordinary weigher can be used, while in the secondary mixing of the dry and wet mixture, a special weigher should be used, which can be more accurate and convenient. After processing, the dough scrap which is produced in the forming process also needs to be recycled and mixed with the raw materials. The quantity and mixing method of the dough scrap will ultimately affect the quality of the chips, so attention must be paid to control.

Equipment: Batch-Type Homogenizer Mixer

Batch-type homogenizer mixer uses intermittent type mixing technology. The structure of it is that a horizontal rotating agitator is designed in a transverse rotating shell. The agitator has left and right rotating blades and the agitator rotates at a high speed, while the shell rotates at a reverse slow speed. The agitating shaft is a hollow shaft, and the liquid ingredient is sprayed from the nozzle to the flying powder through the hollow shaft, then mixed.

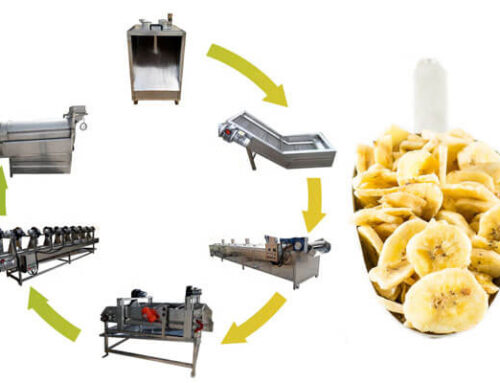

2. Conveying

The mixed material is conveyed to the pressing process through the conveyor belt.

Equipment: Screw Conveyor, Dough Feeder Conveyor belt

The front of the material conveying equipment is a storage bin, and the mixed materials are put into the storage bin intermittently. The upper part of the storage bin is a circular tank, and the lower part is a conical grinding device, which can break the small dough in the raw material and make the raw material uniformly and continuously pass through the spiral feeder to the pressing process. The bin also has a temperature control device, which can control the raw materials at a constant temperature. It is a necessary condition for the full blending modification of raw materials.

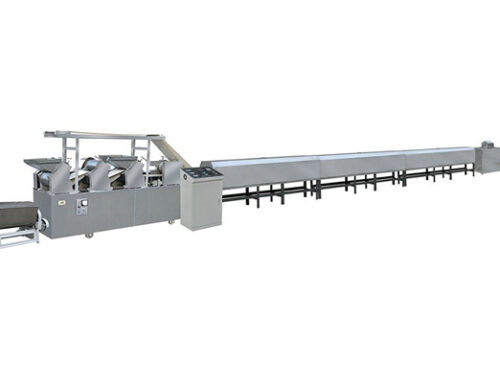

3. Pressing

Requirements for the pressing process: the sheet must have uniform quality, soft texture, stable viscoelasticity, and dimensional accuracy. In order to meet the above technological requirements, potato sheets should be pressed at one time and not more than twice. Because the water will enter potato granules and the granules will swell during pressing, the rheological properties of the granules will be changed. Pressing is more sensitive to shear stress, and the compactness of the sheet structure makes it impossible for the moisture on the outer surface to leave easily. Bubbles will be produced during frying, and the products are not crispy.

Equipment: Three Roller Pressing Machine

The compound potato chips press is designed into three rollers and two-pass rolling according to the technological requirements. The design of three-roll and two-pass rolling has two advantages. One is that the distance between two passes is relatively short. The other is that the sheet can be attached to the roll and dragged into the second passes. The number of raw materials entering the press should be greater than the required amount of the press. Therefore, the feeder must have the function of overflowing surplus raw materials, and the overflowing raw materials must automatically flow back into the storage bin.

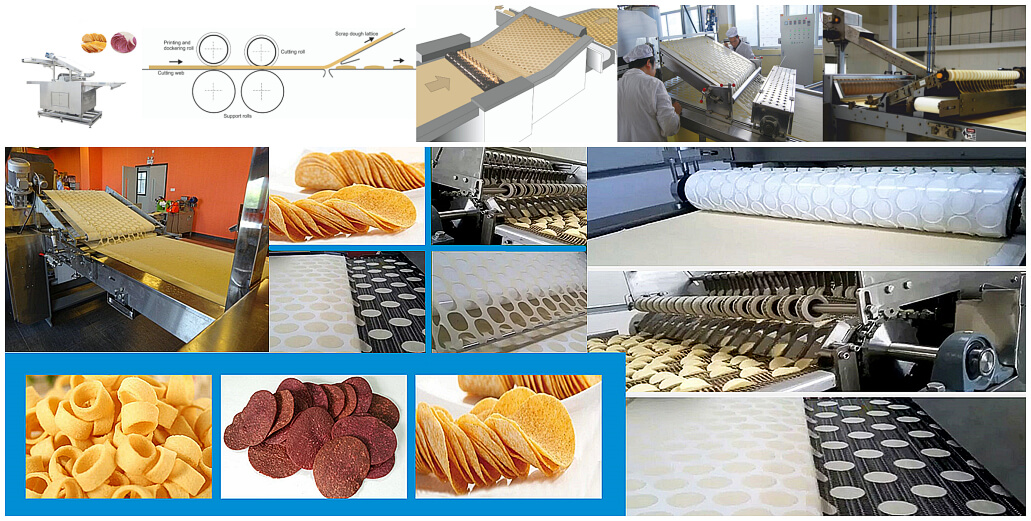

4. Forming

When the sheet is driven by conveyor belt and passed between two forming rolls, a die cutter is installed on the forming roll, and the sheet is cut into blanks and scrap. The blank must be conveyed to the frying process orderly in its original position.

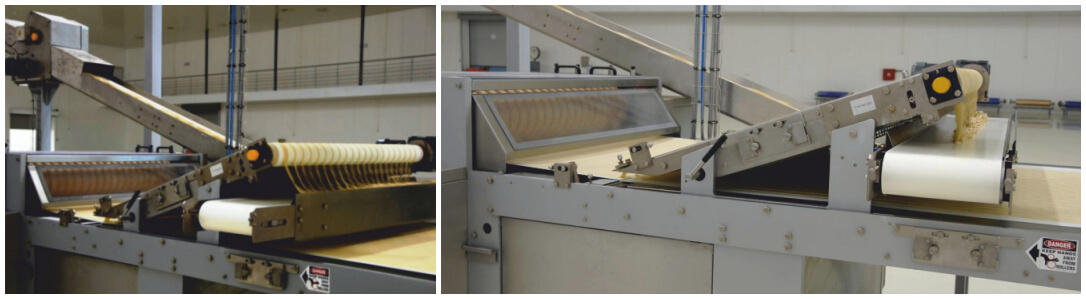

Equipment: Two Rolls Forming Machine

The forming machine is composed of die-cutting roll and anvil roll. The sheet is driven by conveyor belt and cut into blanks by a die-cutting knife. The blanks remain in the original position of the conveyor belt, continue to move along with the conveyor belt, and eventually sent to the fried mesh belt.

5. Scrap recycle mixing

After the blanks are formed, the sheet still has 36%~40% scrap. The scrap is an overall mesh structure, which is conveyed into the scrap processor through the recycling belt. After treatment, the scrap is sent to the storage bin and prepared to be mixed with raw materials.

6. Frying

The frying mesh belt consists of upper and lower layers. When the two layers of mesh belt are combined, an arched mold cavity is formed, which ensures that the blanks can obtain the typical arched shape of potato chips while frying, and can control the relative height of potato chips in the frying tank. Generally, the temperature of frying oil is controlled from 170 to 185 ℃. When processing, the frying oil should keep constant temperature when frying the same variety for 15 to 20 seconds.

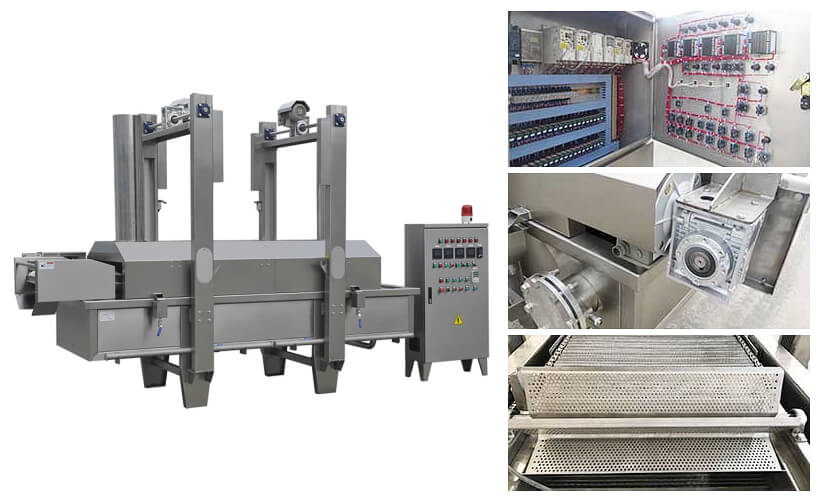

Equipment:Continuous Fryer

The fryer is a box structure with deep-frying oil in it. The frying oil has a circulating filtration system, which can filter and supply the frying oil regularly. The heating method is indirect heating with heat conduction oil. The heat source is a diesel boiler. By heating the heat exchanger under the frying oil, the temperature of the frying oil can be raised and the constant temperature can be guaranteed when the frying oil is working.

Please note: In order to obtain high-quality compound potato chips, it is necessary to filter the frying oil, and the recovery of volatile oil should also be considered.

7. Seasoning

Seasoning is by preparing condiment powder, which requires the powder to be uniformly coated on the surface of the chips at a certain temperature. The design is to suspend and rotate the chips in the airflow which contains a certain concentration of condiments so that all the surfaces of the potato chips have the chance to coat with condiments.

Equipment: Powder Seasoning Machine

The condiment seasoning machine is a two-layer cylinder structure with spiral channels between the inner and outer layers. The inner layer is an open cylinder, and the outer layer’s upper base is sealed with breathable cloth, leaving space between the outer layer’s upper base and the inner layer’s upper base. When the product is conveyed to the lower inlet of the spiral channels, the product is rotated upward along the spiral channel by suspension from the bottom to the top under the action of airflow. The airflow contains a certain concentration of condiment powder, and the chips are coated with condiment as the chips are suspending and rotating in the spiral channel. The airflow is released and filtered by breathable cloth on the top of the outer cylinder. When the potato chips are blown to the top of the inner cylinder by airflow, they fall from the inner cylinder because of the airflow decompression, thus completing the condiment coating process.

8. Cooling and stacking

The potato chips are in a disorganized state after seasoning. The process is to rearrange the chips in a row in a certain direction for conveying and cool them to room temperature at the same time.

Equipment: Cooling and stacking Belt

The task of the cooling stacking machine is to arrange the disorderly products after seasoning.

9. Packaging

After stacking, the potato chips are orderly in a neat row and in a precise direction, running on the conveying belt to prepare for the packaging of the products.

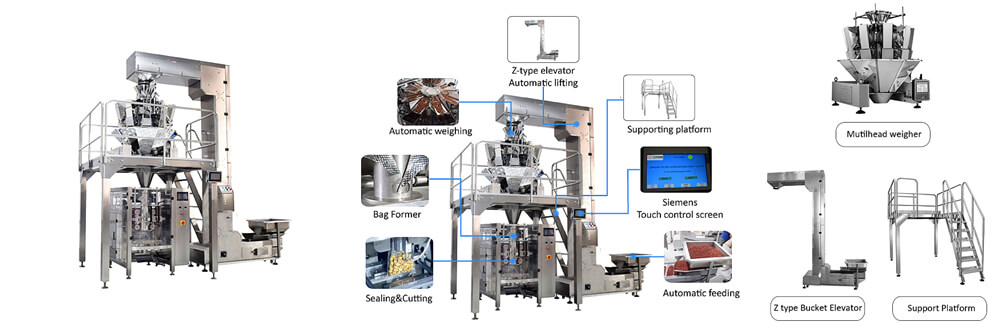

Equipment: Automatic Granule Packing Machine

This machine completes the whole packing procedure of measuring, loading materials, bagging, date printing, air inflation (exhaust), counting, etc. The whole machine design conforms to GMP standard. The main steps include: the potato chips are manually put into the bin of the vibration feeder, then the chips are automatically conveyed by the Z-type material hoist, next the chips are weighed by the automatic weighing according to the set weight, and the chips are bagged by the automatic bagging of the automatic filling and packaging machine, finally the potato chips are transported by the finished product conveyor, and the qualified finished products are transported for the manual box packing.

Compound Potato Chips Production Line Advantages

1. High-quality Finished Potato Chips

Continuous automatic production processes ensure consistent quality of finished products.

High-speed homogenizer ensures homogeneous mixing.

2. Low Oil Loss

Special design to prevent moisture from entering frying pans.

Continuous production without oil drainage.

3. Top Quality

The equipment is made of 304 stainless steel. The food contact part and most other parts of the machine are made of stainless steel. The whole line runs stably and has a high degree of automation. Products can be packed in vertical bags or paper cans. The market demand for chips is large, its sweet and delicious taste makes it suitable for all ages.

4. Accurate Control of Frying System

Continuous frying pan, oil circulation between oil filtration system and heat exchanger provides precise temperature control in the feeding area.

With one high-temperature oil pump for production and another spared oil pump standby, the frying process can be automatically converted without shutdown.

5. Excellent Oil Quality

The rapid flow of old and new oils and ultra-low oil volume ensure the freshness of the potato chips, extend the shelf life of the chips and always automatically maintain the best oil level.

Circulating oil can effectively remove suspended debris. 100% of the oil in the circulating system will be filtered continuously through the filtration system to effectively ensure the quality of oil products and finished products in oil pans.

6. Waste Recycling

Complete mixing of new materials and scrap waste after recycling.

High-efficiency mixer.

7. Controllable Equipment

Technical parameters of control and management of the electronic control box.

The PLC control system can be equipped.

Four Characteristics of Compound Potato Chips

The compound potato chips have good sensory characteristics, delicate taste, rich nutrition, fresh potato’s flavor, moderate sweetness, and crisp texture, making the taste thick.

1)Flexibility

Comparing with other potato foods, it has more flexibility in product shape, variety, especially in product taste, flavor regulation, oil content control and so on.

2)Freshness preservation

Paper composite cans and other hard containers are mostly used for packaging. Compared with the same weight of fried potato chips, the packaging volume is greatly reduced and the shelf life is greatly increased.

3)Convenience

Paper composite cans packaging, not easy to break, easy to carry; open the packaging can, ready to eat; do not have to eat all at once, easy to eat.

4)Health

Compound potato chips are made of natural potato and potato modified starch, which is rich in vitamin C, calcium, phosphorus, magnesium and other nutrients. In the frying process, the oil content of potato chips can be flexibly controlled, which greatly reduces the heat of potato chips, makes chips more nutritious and healthy to eat.