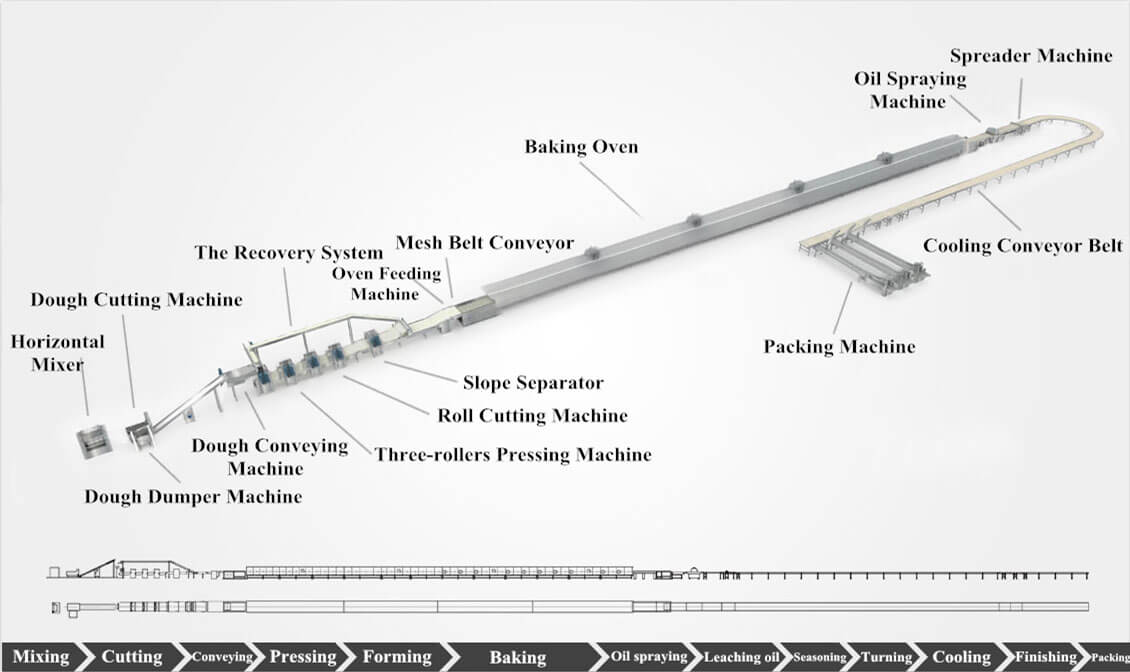

Compound Potato Chips Baking Production Line Introduction

Compound potato chips baking production line is a new generation of non-fried compound potato chips equipment developed and produced by our factory according to the technical characteristics of compound potato chips and biscuit production line. By using potato flakes as the main raw material, the equipment will press potato chips, bake them naturally in a tunnel oven, and then make them into healthy, non-fried compound potato chips. The equipment has the features of high automation, simple & stable operation and lower cost. It conforms to the trend of modern food development and is welcomed by food manufacturers at home and abroad.

Compound Potato Chips Characteristics

1) Compound potato chips are produced from potato whole powder, potato starch, and other primary processed products. The selection of processing location is not as strict as that of fried fresh-cut potato chips.

2) Compound potato chips are processed and produced by compound technology. Compared with other potato foods, they have more flexibility in shape, variety, and specifications, especially in taste, flavor regulation and oil content control of potato chips.

3) Compound potato chips are mostly packed in a paper composite can and other rigid containers. Compared with the same weight of fried fresh-cut potato chips, the packaging container is greatly reduced and the shelf life is greatly increased. In paper can package, not only can the cost of transportation and storage of products be reduced, but also consumers feel convenient to eat, catering to the consumption habits of most consumers.

Equipment Description of Compound Potato Chip Baking Production Line

Fully automatic baking potato chips production line is a modern and popular product line for nutrition and health food. First of all, the powder is mixed through automatic mixing machine, then the dumper pours dough into the hoppers of automatic lifting conveyor. Through the automatic lifting conveyor, the dough is conveyed into dough pressing machine, and it is formed by rolling-cutting machine after three-rollers pressing machine. After baking, the potato chips are sprayed oil, next, potato chips are cooled by cooling line after spraying condiment through seasoning machine. Then it is packed by packing machine.

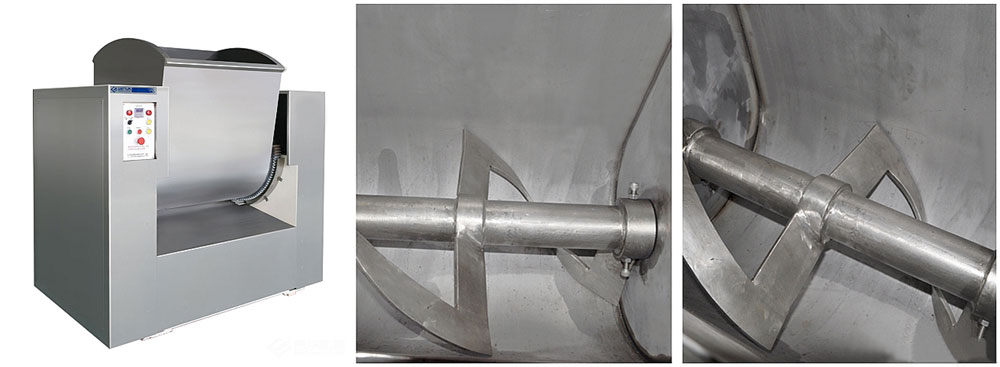

1. Horizontal Mixer

Horizontal dough mixing machine is used to make a dough. After kneading, calendering and folding in the process of stirring, the dough with a smooth surface, good elasticity, toughness, and extension are prepared. The machine is suitable for mixing material which is used to make compound potato chips and crisp biscuits.

The mixing machine has the structure of a complete machine base. The transmission system runs flexibly and smoothly. The workpieces contacted by the mixing paddle and materials are made of stainless steel. The mixer has good corrosion resistance and can maintain the quality of the mixture material so that it does not pollute or change color. The transmission system mainly adopts the direct transmission of the turbine and worm. It has no excessive noise and enough oil storage. It can get good lubrication and improve the service life of the machine. This mixing machine is controlled and operated by electrical device, which is easy to operate and adopts point-moving feeding to reduce the labor intensity of the operator.

2. Dough Dumper Machine

2. Dough Dumper Machine

By turning over the dough bucket together with the dough in the dumper, the dough is dumped into the dough trough in the dough cutting machine. The conveyor belt at the bottom of the dough trough conveys the dough to the knife cutting part. The knife cuts the dough into lighter weight dough to realize the long-distance transportation of the dough. The working efficiency can be improved by using the dumper.

3. Dough Conveying Machine

3. Dough Conveying Machine

The dough conveyor belt delivers the dough to the rolling device.

Please note: such as the crisp dough which needs to be crushed by the crushing device, and then conveys the dough to the hopper through the slope.

4. Three-rollers Pressing Machine

The three-roller mill presses dough three times to make the dough thin from thick, and forms a uniform corrugation by the loosening mechanism, eliminating the residual internal stress of the dough, so as to meet the requirements for the production of compound potato chips.

The surface of the roller is polished by a grinder, which is smooth and beautiful, and the pressed dough sheet is even and smooth, thus ensuring good sheet quality. The machine adopts arrangement, reducer and sprocket drive, with characteristics of low noise, compact structure, humanized design, and labor saving. It is easy to operate, safe and hygienic, and easy to see. With smooth transmission, accurate and efficient transmission power, no vibration, superior performance, and other characteristics, the pressing machine is the ideal product of compound potato chips production enterprises. Its main parts adopt 45 # forged steel gears, and the rollers adopt 45 # seamless steel tube. After heat treatment, the hardness of the rollers is increased, and the pressed sheets are more smooth and tenacious.

5. Roll Cutting Machine

5. Roll Cutting Machine

The roll cutting machine is a molding device for making compound potato chips. The dough sheet is formed into blanks after passing through a roll cutting machine, and the remaining scrap is separated by a separator and recycled to the feeding hopper through the recovery system.

The forming machine consists of a printing roller and a cutting roller. The machine has low noise and high speed. Generally, the maximum speed of it can reach more than 50 meters per minute. Moreover, the formed blanks have a uniform shape, good surface finish, and fine texture. When the machine starts, the conveyor belt carries the sheet first through the printing roll for pressing and then through the cutting roll for cutting. After separating the cut blanks from the scrap material, the blank is sent to the oven by the conveyor belt for baking. Under the conveyor belt, there is a carrying idler with a large diameter, its diameter is generally between 400 and 600 mm. It can run freely with the belt pressed on it. The carrying idler is coated with an oil-resistant rubber to make it hard and elastic enough. In roll printing and cutting, it withstands the pressure of the printing roller and cutting roller, and demoulds the cut blanks.

6. Slope Separator

6. Slope Separator

After rolling cutter, the blank is formed, and the dough scrap residues are returned to the lower feeding hopper by the recovery system of the separator.

7. The Recovery System

After the dough is passed through the roll cutting machine, a dough blank is formed, and then the remaining material of the scrap is separated by the slope separator, and sent to the recovery machine and then sent to the hopper of the three-rollers pressing machine.

8. Oven Feeding Machine

8. Oven Feeding Machine

The oven feeding machine connects the forming machine to convey the blank to the oven mesh belt.

9. Mesh Belt Conveyor

The machine is used for oven mesh belt conveying.

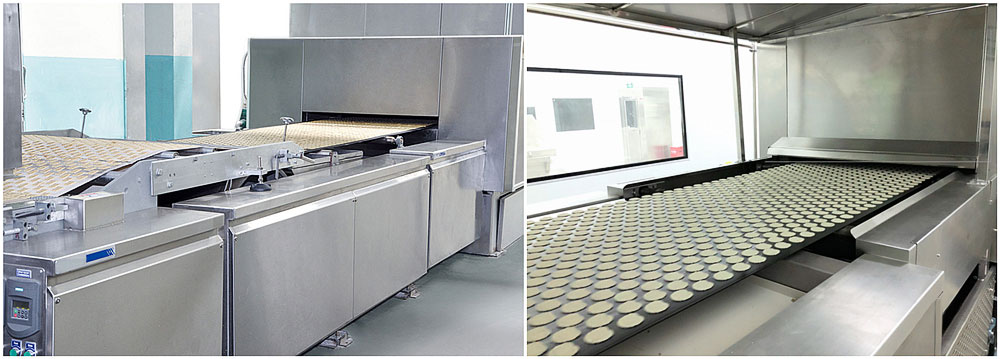

10. Baking Oven

10. Baking Oven

- Steel structure hot air circulating gas oven

The most commonly used oven is using liquefied petroleum gas or natural gas as energy, adapting imported brand burners, with advantages of high combustion heat efficiency, low energy consumption, more scientific and safe than the traditional oven, compact steel structure, good shape, good thermal insulation, fast heating, environmental protection, simple operation, and programmable. Through gas centralized heating oven and hot air circulating fan, the air convection cycle is formed by drawing air from the top of the oven to vent at the lowest level of the oven, which ensures uniform temperature and uniform color of the baked potato chips. It is heated by an imported burner from Italy.

- Hot air circulating electric heating oven

Hot air circulating electric heating oven uses electricity as baking energy and far infrared electric heating tube as heating energy. It has high energy efficiency, long service life, and simple maintenance. The oven adopts fully automatic temperature control system with solid state relay as actuator ensures constant oven temperature. Each temperature zone of the oven has an independent hot air circulation system to improve efficiency and fast heating. Baked potato chips have good taste, uniform color, and beautiful appearance.

The electric heating tube is used as the heat source carrier in the mesh belt type hot air circulating electric heating oven. It is placed at the bottom of the oven and the air is forced to blow through the electric heating tube by the fan. Thereby, hot air convection and circulation are generated, so that potato chips placed in the mesh belt conveying are evenly baked. The baking temperature can be set by adjusting the temperature controller, and the temperature sensor located in the middle of the inner wall of the oven feeds back the temperature to the temperature control system in time. The conveying speed of the mesh belt can be changed by adjusting the step-less speed-regulator in a certain range so that the food placed on the mesh belt can get the corresponding baking time. It can be seen that only by adjusting the parameters of the temperature controller and step-less speed-regulator, the different baking process requirements of various foods can be met.

When baking, the heating system starts, and the heat generated by the electric heating tube is forced to blow from the bottom of the oven to the inner oven by the fan. At the same time, the mesh belt is driven by the variable speed motor to rotate at a uniform speed, so that the potato chips placed on the mesh belt are sent from the entrance of the tunnel to the inner oven for baking, and then the potato chips are discharged from the outlet of the tunnel.

The whole baking process can generally be divided into three stages. In the early stage of entering the oven, the temperature of the entrance is lower and the relative humidity of food is higher, which can avoid the phenomenon of fast consolidation of the food surface; the second stage of baking: when the food moves to the middle of the oven and bakes at the set baking temperature, the food can be formed and baked; the third stage of baking: when approaching the final stage of leaving the oven, the temperature of the outlet gradually decreases, this section of baking mainly produces brown skin on the surface of food and increases the fragrance of finished products. At this time, if the oven temperature is too high, the skin of food will be scorched.

- Steel structure gas mixing oven

The oven has many combination modes, the most commonly used is liquefied gas or natural gas as the energy source, the liquefied gas part of the oven uses direct combustion heating method, and the natural gas part of the oven uses a burner with hot air circulation convection heating method. The gas mixing oven is mainly composed of segmented baking oven, electrical device, and various auxiliary equipment. It uses a programmable controller (PLC) as the core and is equipped with an LCD touch screen, which can meet the baking process requirements of all kinds of chips.

11. Oil Spraying Machine

The device is used for spraying oil on the upper and lower surfaces of potato chips, which can make the surface of potato chips have a bright and moist feeling, and the taste is more crisp and delicious. The spraying machine adopts centrifugal disc-throwing type, which can spray oil on both sides of potato chips at the same time. The machine is equipped with an oil mist collection system, to achieve uniform oil injection, the working environment is basically free of oil mist pollution.

12. Spreader Machine

12. Spreader Machine

The machine can sprinkle the potato chips after baking to meet the demand for seasoning technology.

13. Cooling Conveyor Belt

The cooling conveyor is to let the baked potato chips cool and set under normal conditions. Pneumatic tension and automatic deviation adjusting device are used in the conveying system.

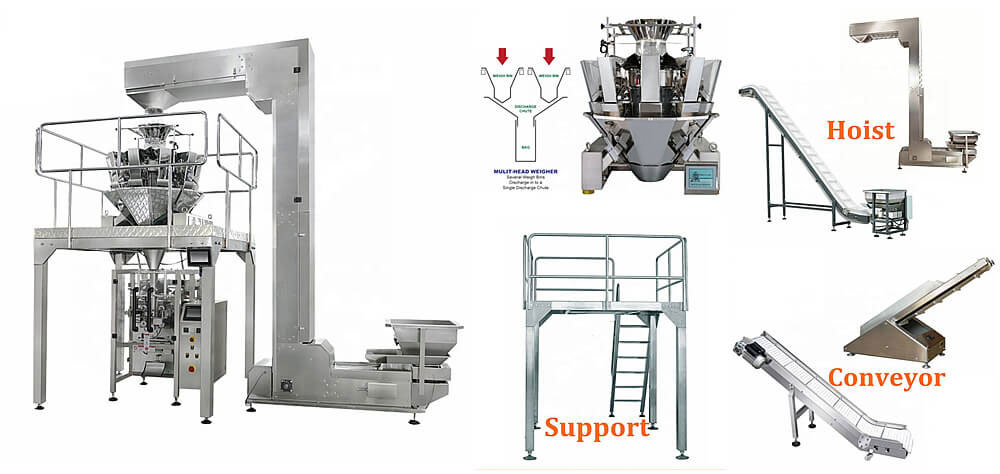

14. Packing Machine

The packing machine is connected with the finishing machine to facilitate workers to pack or transfer the finished potato chips to the packaging machine.

Compound Potato Chips Baking Production Line Advantages

High-automation

The whole production line has a less manual operation and high automation. The equipment is programmed and controlled by plc. The production efficiency is high. The tunnel baking oven saves 30% energy than the general tunnel oven, which is deeply loved and trusted by major food enterprises.

Healthy food

The advantage of the equipment is that the produced compound potato chips are not only coarse grain products but also non-fried food, which is suitable for the current leisure and healthy food consumption concept.

Multifunctional

Potatoes, sweet potatoes, cassava, carrots, and other root-stem vegetables can be processed as raw materials.

Safe

The whole processing line is made by 304 stainless steel which meets with safety standards of food machinery.