Integrated Screw Oil Press Instruction

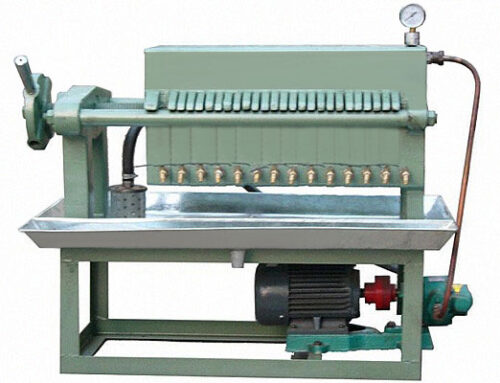

Integrated screw oil press is a compound machine which can squeeze and filter oil and at the same time, squeeze many oil crops including peanuts, soybeans, tea seeds, and cottonseeds etc.

Integrated Screw Oil Press Application

Integrated Screw Oil Press Application

The automatically integrated screw oil press adopts the newest technology and qualified stainless steel, with high oil yield and vacuum filtering. It is ideal for hot pressing of sesame, soybeans, rapeseeds, cotton seeds, tea seeds, sunflower seeds, castor seeds, and almonds etc. Also, it can be used for cold pressing of other oil materials. The integrated screw oil presses are widely used in small-sized and medium-sized oil plants.

Integrated Screw Oil Press Features and Benefits

Integrated Screw Oil Press Features and Benefits

★Advanced Technology: reliable performance, easy operation, and convenient maintenance.

★High oil yield: compared with the old-style equipment, the oil yield can increase 2%-3%.

★Lower Power Consumption: integrated screw oil press can decrease 40% power with the same output.

★Wide usage: the automatic screw oil press can press multiple oil crops, such as peanuts, sesame, sunflower seeds, and soybeans etc.

★Pure oil: vacuum filtering device of the automatic screw oil press can ensure the pure oil conforming to the health and quarantine standard.

★Automatic control: this oil press can control the squeezing temperature automatically; built-in vacuum shunt can make the efficient separation of oil and residue.

★Covering small floor space: only 10-20 square meters can satisfy the oil processing machine.

Integrated Oil Press Working Principle

When the oil press runs, the processed oil materials enter into the squeezing chamber through the hopper. The screw rotor propels the oil materials inward and squeezes them. The oil materials in the squeezing chamber are motorial. In the high-pressure chamber, there is great friction resistance between oil materials and squeezing spiral or squeezing chamber, thus the micro materials can create friction. On the other hand, the squeezing screw diameter is gradually thickening and the screw pitch is gradually decreasing, so when the squeezing screw rotates, the screw threads can propel the oil materials forward or outward. The heat generated by friction can improve the yield of the oil press, and let the oil flows from the gaps. When the overflowing oil flows onto the oil filtering barrel through the oil tray, the vacuum pump pumps the air in the barrel, and then negative pressure forms in the barrel. The oil is pumped into the barrel through the filtering cloth and the oil residues are left on the filtering cloth.

Difference Between Cold Pressing and Hot Pressing

1. The cold pressing of oily seeds does not require any preconditioning of the input material. The only requirement is that the input seed is 98% clean and free of metal and stone particles. The hot pressing of oily seeds should be roasted in advance.

2. The cold pressed oil has better color and luster than hot pressed oil; however, the hot pressed oil smells better than cold pressed oil.

3. The cold pressed oil has lower oil yield than hot pressed oil.

4. When choosing between cold and hot pressing technologies, one must always consider the intended use of the produced vegetable oil, as well as other factors influencing return.

Integrated Screw Oil Press Technical Parameters

| Model | Capacity | Power | Weight | Dimension |

| 6YL-80CA | 3~4 Ton/Day | 7.5Kw | 730kg | 2050*980*1700 mm |

| 6YL-95CA | 3~5Ton/Day | 7.5Kw | 810kg | 2100*990*1750 mm |

| 6YL-100A | 3~5Ton/Day | 7.5Kw | 810kg | 2100*990*1750 mm |

| 6YL-120A | 4~6Ton/Day | 11Kw | 970kg | 2250*1100*1750 mm |

| 6YL-120CA | 6~8Ton/Day | 15Kw | 990kg | 2250*1100*1850 mm |

| 6YL-130A | 9~12Ton/Day | 18.5Kw | 1150kg | 2500*1200*1900 mm |

| 6YL-160A | 15~20Ton/Day | 22Kw | 1450kg | 2500*1200*1900 mm |