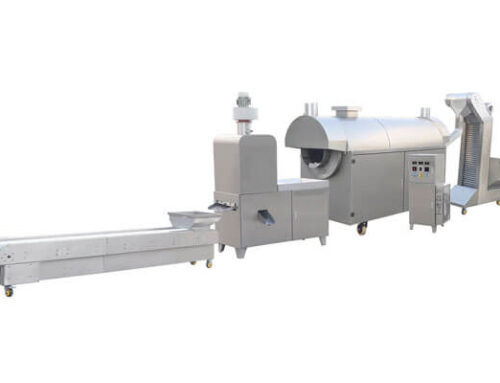

Walnut Cracking Machine Introduction

Walnut cracking machine is suitable for cracking walnut of different sizes and varieties. You can use this walnut cracker machine to crack English walnut, black walnut, pecan, and hazelnut, almond, macadamia nut, etc. It is an ideal walnut cracking equipment. This walnut shelling machine is used with walnut shell and kernel separating machine to separate walnut kernels from broken shells.

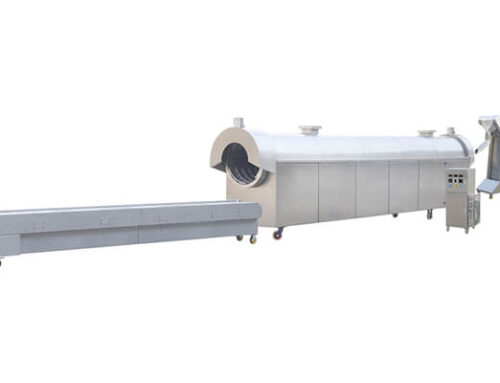

Based on the difference in the specific gravity and suspension velocity, walnut shell and kernel separator separates walnut kernels from shells with the aid of upward air flow. The deck tilt and air volume of the separator machine can be adjusted to achieve better separation effect.

Features of Walnut and Pecan Shelling Machine

1. High efficiency, high quality, low power consumption, easy operation and maintenance.

2. High cracking rate and high whole kernel rate, high separation rate.

3. The internal clearance of the pecan shelling machine is adjustable.

4. The deck tilt and air volume of the walnut separating machine is adjustable.

5. This pecan cracking machine is suitable for cracking walnut of different sizes and varieties.

How to Operate Walnut Cracker Machine?

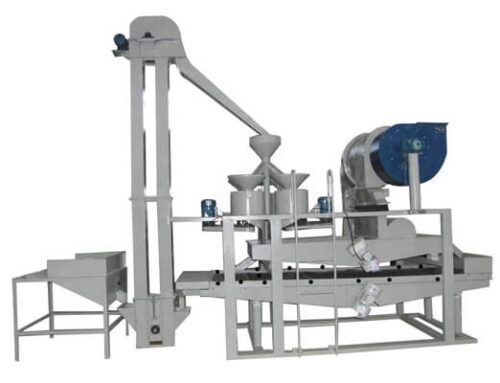

1. Walnut cracker machine can crack walnut of different sizes by adjusting the internal clearance. It’s better to grade walnuts by walnut grading machine before cracking by the pecan shelling machine.

2. Depending on the varieties of walnut, the capacity and whole kernel rate are different. The internal clearance of the pecan cracking machine can be adjusted to achieve the best shelling effect.

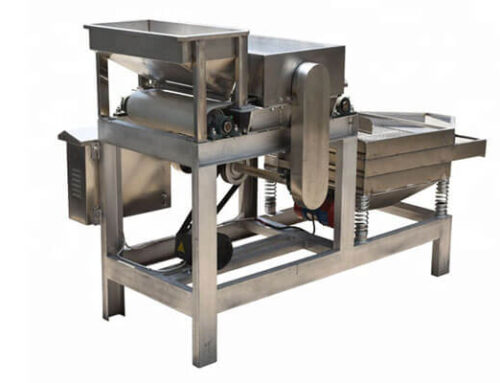

3. Walnut shelling machine consists of frame, hopper, roller, and outlet. Walnuts are fed into the hopper of the machine, being shelled inside and discharged out afterwards.

4. The mixture from walnut cracking machine is fed into walnut shell and kernel separator to separate kernels from broken shells. Please spread the walnut kernels full on the vibration table for better effect.

Technical Data of Walnut Cracking & Separating Machine

| Function | Cracking | Separating | Cracking | Separating |

| Model | HT-1 | FL-01 | HT-2 | FL-02 |

| Capacity(kg/hr) | 200-300 | 200-300 | 600-800 | 1000 |

| Power | 1.5 kW/380 V | 2.2 kw/380 V | 2.2 kW/380 V | 4kw//380 V |

| Rate | >95% | >98% | >95% | >98% |

| Whole Kernel Rate | >70% | / | >70% | / |

| Dimension(mm) | 1300*700*1300 | 1970*920*1350 | 1600*1600*2200 | 3500*1100*1650 |

| Weight (kg) | 230 | 230 | 360 | 360 |