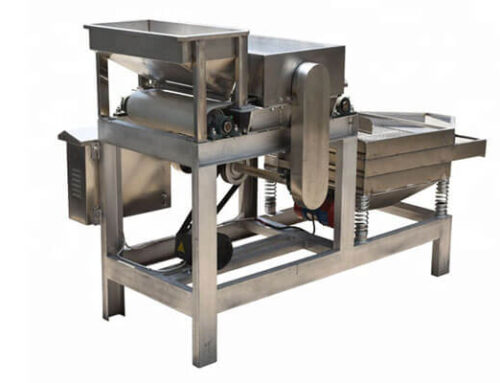

Peanut Shelling Machine Introduction

Peanut shelling machine is to remove peanut hard shell by high-speed rotation, and at the same time, keep the peanut kernels as integral as possible. It is an ideal nut shelling machine in fruit and snack processing plants of different sizes.

Peanut Shelling Machine Features

☆Multifunctional for shelling peanuts, cashew, broad bean, etc.

☆Automatically separate peanut shells and peanut kernels, labor saving.

☆Clean shelling processing, high efficiency

☆Low broken rate and loss.

☆Simple design, easy operation.

☆Durable, adjustable and energy saving.

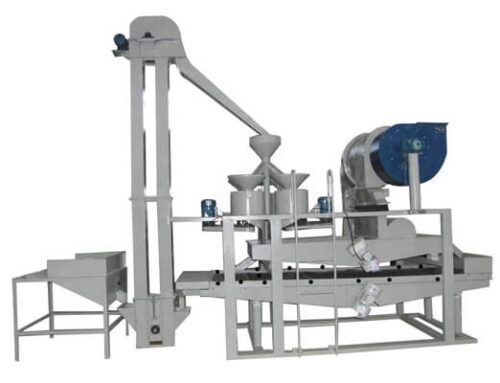

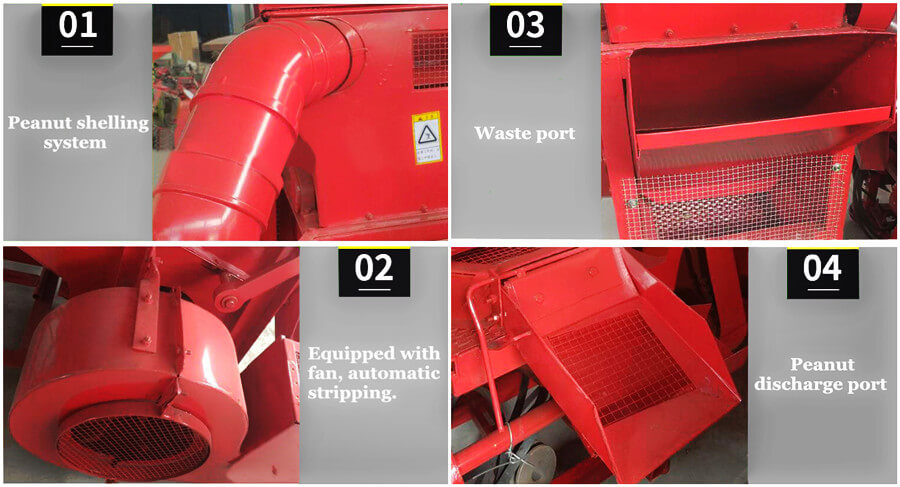

Peanut Shelling Machine Structure and Working Principle

It consists of a fan, gravity separation device, screen, rotors, and elevator. After starting, peanuts are fed evenly in a certain quantity. The rotors keep beating and crashing peanuts until that the shells are broken. Peanut kernels and broken peanut shells go through screens. Due to the fan blowing and screen vibrating, the lighter peanut shells are blown out and we can get the clean peanut kernels easily.

The Requirement for Shelling Peanuts

Moisture content is important. Peanuts stored in the countryside are always too dry. We can sink them in a large pool, then fish them out immediately and cover them by the plastic film. One day later, uncover them for blowing or shining about 1 hour. Then they can be shelled.

Peanut Shelling Machine Parameters

| Model | BK-3 | BK-5 |

| Capacity | 500—700kg/h | 800-1000kg/h |

| Power | 3Kw | 4Kw |

| Voltage | 380V | 380V |

| Broken rate | ≤5% | ≤5% |

| Peeling rate | >95% | >95% |

| Damage rate | ≤5% | ≤5% |

| Dimension | 120*60*142 | 140*95*176 |