Introduction to Peanut Kernel Grading Machine

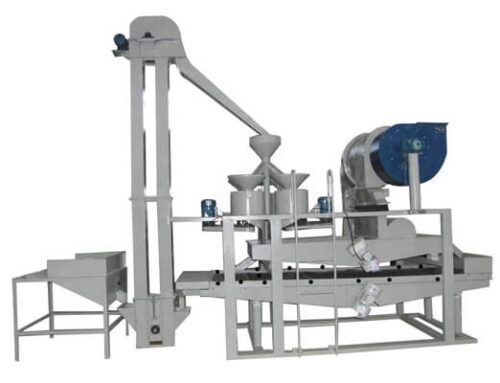

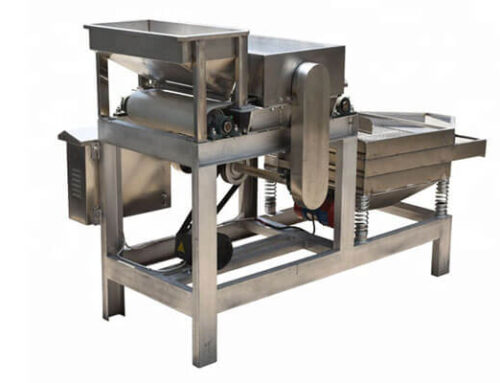

Peanut kernels grading machine is mainly used for grading peanut kernels. The machine can sort peanut kernels into 4 or 5 different sizes at one time. The sieves of the screening machine can be changed to meet different demands. This peanut grading machine is also suitable for classifying almond kernels, hazelnut kernels, macadamia nuts, soybean, broad beans, etc. We also supply peanut shelling machine, peanut peeling machine and other peanut processing machines.

Advantages of Peanut Grading Machine

1. Compact and reasonable structure, high efficiency, low energy consumption.

2. Convenient operation, reliable performance, automatic feeding, exact grading results.

3. There is material returning plate under each layer of sieving body, avoiding the materials fall down to the lower layer without being sieved.

4. The inclination of the sieving body ensures the smooth discharging of the materials.

5. The machine can not only process peanut kernels but also can process almond kernels, hazelnut kernels, and other kernels.

Working Principle of Peanut Sorting Machine

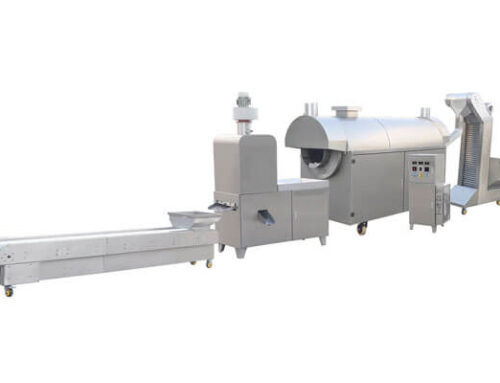

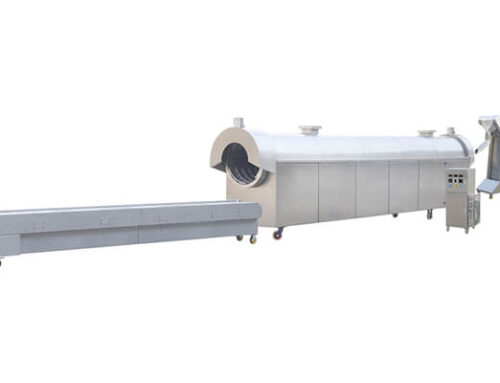

Peanut sieving machine consists of hopper, elevator, sieving machine, supporting base, kernels collector, etc. The peanut screening machine adopts chain wheel and chain to drive the pushrod, resulting in smooth reciprocating sieving of the sieving body.

Peanut kernels are fed by vertical bucket elevator into the upper layer of screen body. Under the shaking of the screen, peanut kernels are graded into 4-5 sizes. Larger sizes of kernels will come out from the upper outlet of the peanut grading machine.

Tips for Groundnut Kernels Grading Machine

1. Evenly feeding ensures better sieving effect.

2. Please lubricate the chain and bearing regularly to prolong the service life.

3. An additional set of sieves is equipped for replacement according to the size of the peanut kernel.

|

|

|

|

Technical Specifications of Peanut Kernel Grading Machine

| Model | sx800-4 | sx800-5 |

| Capacity | 1 t/h | 1.5 t/h |

| Power | 1.5 kw | 1.5 kw |

| Weight | 1200 kg | 1500 kg |

| Dimension | 5000*1050*2600 mm | 5000*1050*3000 mm |

| Sieve Size | 800*330*40 mm | 800*330*40 mm |

| Sieves per Layer | 4 | 5 |