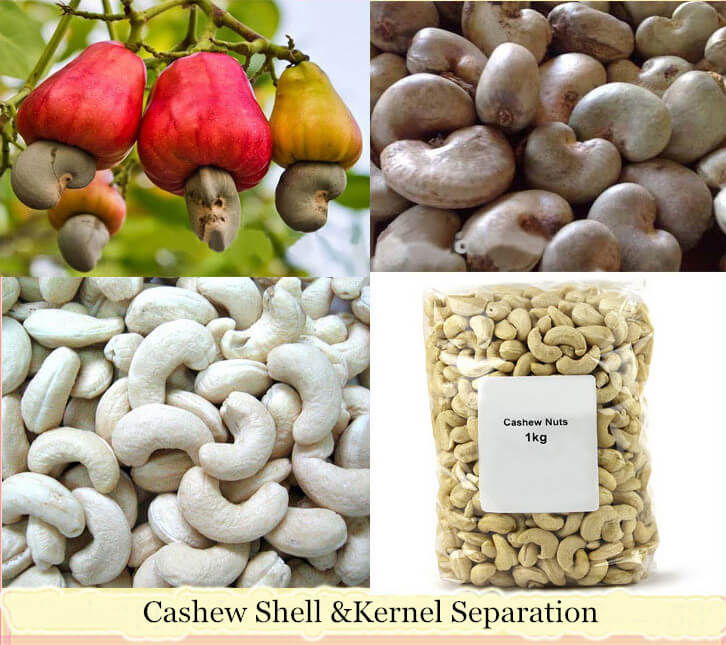

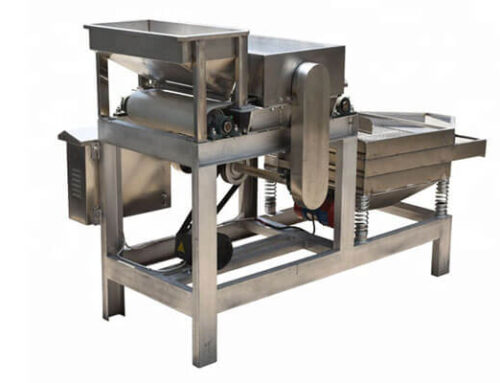

Cashew Shell &Kernel Separating Machine Introduction

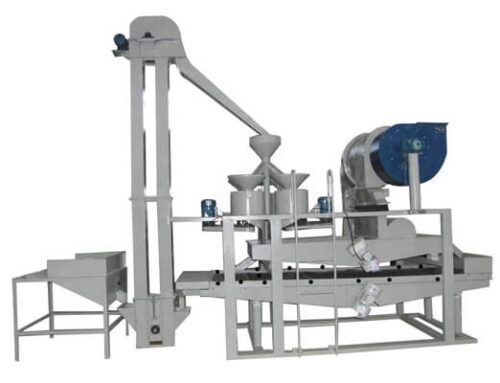

Cashew shell and kernel separating machine is mainly used for separating the kernels and shells after cashew shelling efficiently. According to different sizes of cashew kernels and shells, this separating machine is specially designed to separate the nuts from shells by means of sieve pore. It is one of the necessary equipment for processing raw cashew nuts into varieties of cashew food.

Cashew Kernel Separating Machine Features

◇Fully automatic processing, easy to operate, reliable performance, energy saving.

◇Made of stainless steel material, healthy, easy to clean, durable use.

◇The connection of reciprocating motion is adopted the rubber bearing, which is durable, shock absorption.

◇ High separating rate 99%, little damage.

◇ The machine can be adjusted to change the transfer speed…

◇ Working alone or with other processing devices.

How Does Cashew Shell & Kernel Separating Machine Work

This machine uses the characteristics that cashew kernels and shells are in different size to make kernels and shells separating with the aid of the screen hole size. It can be adjusted the angle of the vibrating screen body to control the material’s transfer speed to achieve the separation effect.

Cashew Shell & Kernel Separating Machine Technical Data

| Model | ALCSM-400 |

| Capacity | 400-500kg/h |

| Power | 1.1kw/380V |

| Dimension | 2000*800*1300mm |

| Weight | 300kg |