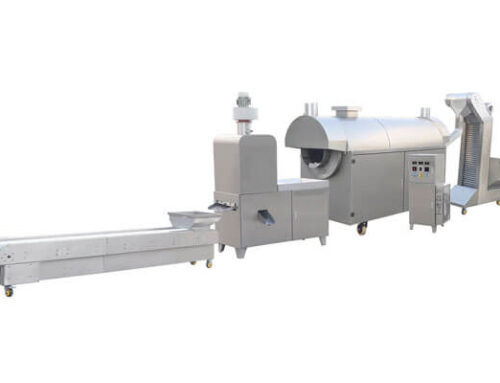

Introduction to Buckwheat Hulling and Separating Machine

We can provide you with buckwheat hulling and separating equipment, which is one of our patented products owing to the independent intellectual property. And it is also widely used with better hulling results all over the world. During the hulling process, the buckwheat kernel-shell can be separated automatically, and meanwhile, the machine can sort out the broken from the kernels. It adopts a dry method hulling process, no preheating to buckwheat required beforehand. The hulling and separating machine features easy operation, high rate of whole kernels and perfect kernel-shell separation work.

Highlights of Buckwheat Hulling and Separating Machine

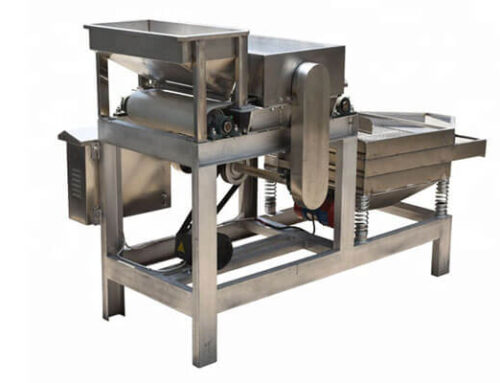

1. The ideal hulling result can be achieved due to the adjustable design of the hullers, the interspace of the emery rollers can be adjusted according to the various materials.

2. The screen mesh is made of premium quality cold rolled sheet, durable service. Prevent mesh from blockage due to the bouncing ball design.

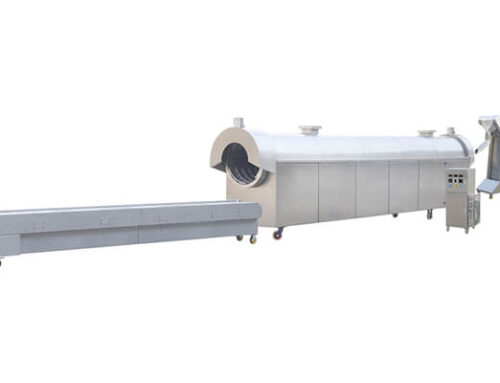

3. The hulling and separating machines adopts the vibrating and negative-pressure separation machine and spiral materials-unloader to make the shells collecting work easier and meanwhile reduce the dust accumulation greatly during the working process.

4. The vibrating source of the equipment adopts a vibratory motors design. This hulling equipment features easy and quick installation.

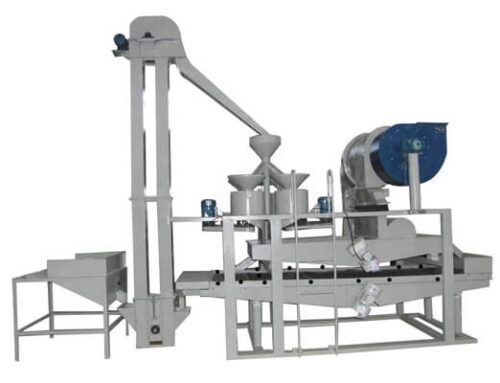

Note: ① hopper ② elevator ③shelling and separating machine ④electric cabinet

buckwheat seeds dehuller |

screen mesh |

negative pressure separator |

vibration motor |

Working Principles of Buckwheat Hulling and Separating Machine

Components: The buckwheat hulling and separating machine consists of feeding hopper, bucket elevator, huller, electric control cabinet.

Working Process: Raw materials → Elevating → Shelling & Separating → Checking the un-hulled buckwheat → Flowing back for Re-hulling → Pure kernels

Technical Parameters of Buckwheat Seeds Hulling Machine

| Model | TFQM400 |

| Capacity | 200kg/h |

| Power Source | 9.84kw/380v |

| Weight | 2200kg |

|

Dimensions (L*W*H)

|

6000*3000*4500mm |

| Perfect Kernels Rate | 98% |

Note: Buckwheat cleaning and grading unit can clean various impurities in the buckwheat seeds, such as big and small impurities, light and heavy impurities, etc., and then divide the buckwheat seed into 6-8 grades. If you are interested in this unit, we can also customize for you.

How to Enjoy Buckwheat

▶ Combine buckwheat flour with whole wheat flour to make delicious bread, muffins, and pancakes.

▶ Cook up a pot of buckwheat for a change of pace from hot oatmeal as a delicious hearty breakfast cereal.

▶ Add cooked buckwheat to soups or stews to give them a hardier flavor and deeper texture.

▶ Add chopped chicken, garden peas, pumpkin seeds and scallions to cooked and cooled buckwheat for a delightful lunch or dinner salad.