Date Pitting Machine Introduction

Date pitting machine, as the name implies, is used to remove date pit from dates flesh without breaking the dates. With the adjustable pitting spaces, date pitting machine has been widely used for pitting different fruits such as dates, apricot, cherry, plum, olive, hawthorn, and etc.

Date Pitting Machine Technical Data

| Type | Rate of pitter | Power | Dimension(mm) | Capacity |

| Apricot pitter | 99.8% | 1.5KW | 20-50mm | 67200 pcs/h |

| Cherry pitter | 99.8% | 1.5KW | 10-25mm | 98400 pcs/h |

| Plum pitter | 99.8% | 1.5KW | 30-40mm | 79200 pcs/h |

| Date pitter | 99.8% | 1.5KW | 12-50mm | 38400pcs/h |

| Olive pitter | 99.8% | 1.5KW | 16-30mm | 57600 pcs/h |

| Hawthorn pitter | 99.8% | 1.5KW | 20-48mm | 43200 pcs/h |

Why Choose Our Date Pitting Machine?

★ The Popularity of Date Pitting Machine

Fruit pitting is the preliminary stage for fruit further processing, thus fruit kernel removing machine is necessary equipment in the most fruit processing industry including canned fruits, candied dates, and bagged dates processing plants which are all used the pitted fruits.

★ Our Date Pit Removing Machine

We offer date pitting machine and other fruit processing equipment at an unbeatable price and you are totally optional for pitting machine material according to your budget and special demand.

★ Date Pitting Machine Features

☆ Automatically pitting and separating, easy to operate.

☆ Adjustable roller spaces to ensure integral pitted fruits.

☆ The parts contact to fruit pulp parts is made of stainless steel material, hygiene.

☆ Adjustable diameter range from 10-34 mm.

☆ High pitting efficiency, large processing capacity.

☆ Multiple functions, can pit dry & green fruits by different models.

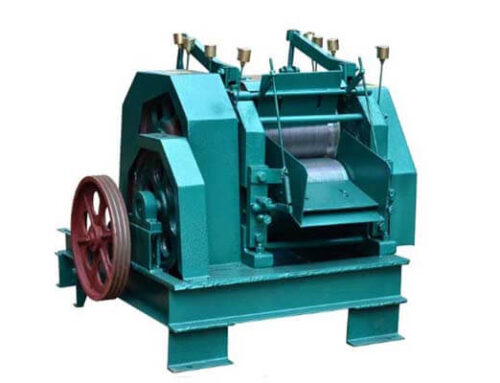

Date Pitting Machine Structure

Mainly composed of the conveyor and the punch-pin, date pitting machine has a unique design. The conveyor is a belt with hundreds of thousands of dots which can be adjusted based on different fruits. It brings the fruits upward to the punch-pin place. The punch-pin pit them line by line and fruit flesh and cores are separated from two discharging holes. The whole pitted process takes a few minutes and you can clearly see the pitted fruits-integrated and clean.