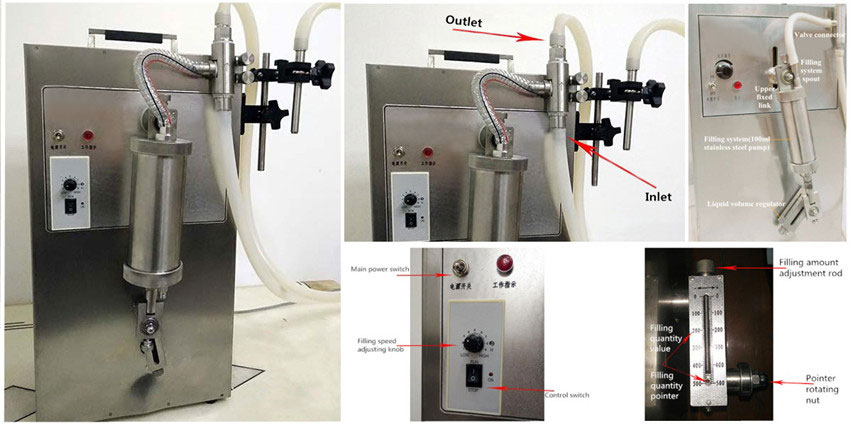

Small Quantitative Liquid Filling Machine

The small quantitative liquid filling machine is a liquid packaging machine, adopts electric, crank, piston design for the quantitative liquid dispensing. It is suitable for quantitative packaging of various kinds of liquid, such as potions liquid, cool and refreshing beverage, cosmetic. This machine is made of high-quality stainless steel, novel, and attractive appearance. It can quantify correctly, the sub-package error is small, can be easily adjusted. The small quantitative liquid filling machine is the ideal small filling and packing devices for small quantitative liquid.

Small Quantitative Liquid Filling Machine Technical Specification

| Model | ALC5-YT012 |

| Power | 60w |

| Voltage | 220V |

| Packing Precision | ±0.5% |

| Overall Dimension | 530*310*250mm |

| Weight | 13kg |

| Filling Range | 10-100ml |

Small Quantitative Liquid Filling Machine Features

1. Used high-quality stainless steel, novel appearance.

2. Simple structure, small volume, reliable, fewer faults.

3. Adopts the cone piston, sealing performance well, good sealing ability and filing accurate and easy to adjust the liquid quantity.

4. The parts contacted with liquid using active connections, easy to loading and unloading, can be sterile sub-injection.

5. This machine’s cylinder, putting, pistons are made of stainless steel, corrosion-resistant, wear-resistant.

6. Adjustable speed, easy to operate.

Small Quantitative Liquid Filling Machine Application

Small quantitative liquid filling machine is applicable to the department of pharmaceutical preparation in hospital, ampoules, eye drops, all kinds of oral liquid, shampoo and various kinds of agent filling the quantitative; At the same time, it also can do all kinds of chemical analysis of the test of quantitative liquid continuous and fluid, can be applied to the large, medium, small pesticide factory small liquid repacking. It is the ideal equipment for small doses of quantitative liquid packing.

Disinfection and Washing of Small Quantitative Liquid Filling Machine

The machine must be kept clean, it is strictly prohibited from oil, medicine liquid or glass fragment, lest causing deterioration of machine.

☆Unscrew upper and lower set screw, and remove the liquid system to do the whole disinfection, or remove separately to do disinfection and cleaning.

☆Put the intake pipe into the cleaning fluid, then turn on the machine to clean.

☆In the production process, cleaning solution or glass fragment in time.

☆After using, clean the machine surface, and add lean lubricating oil in all the activities department.

☆Scrub one time in a week, especially wipe the places that common use but not easy to clean.

Small Quantitative Liquid Filling Machine Fixing Method