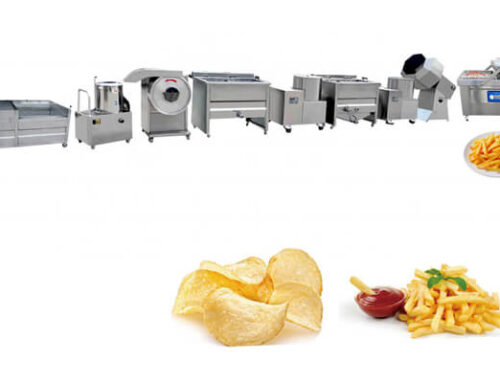

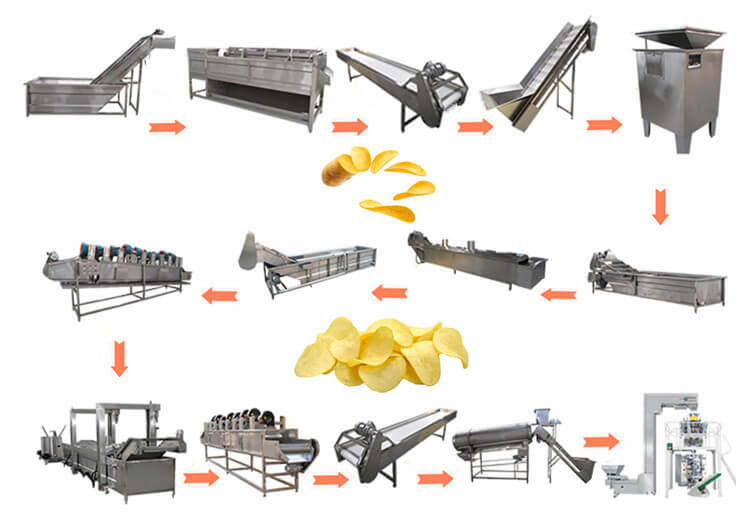

Automatic Potato Chips Production Line Introduction

This automatic potato chips production line is mainly composed of potato washing & peeling machine, potato cutting machine, potato blanching machine, potato dewatering machine, potato chips frying machine, potato chips de-oiling machine, potato chips flavoring machine and potato chips packing machine. Apart from making potato chips and French fries, by using this automatic chips making plant, you could also make frozen French fries (equipped with a freezer).

Characters of Fully Automatic Potato Chips Making Machine

1) The potato chips production line is made up of stainless steel, durable and healthy.

2) Semi-automatic and fully automatic potato chips processing line are offered for your choice according to your capacity.

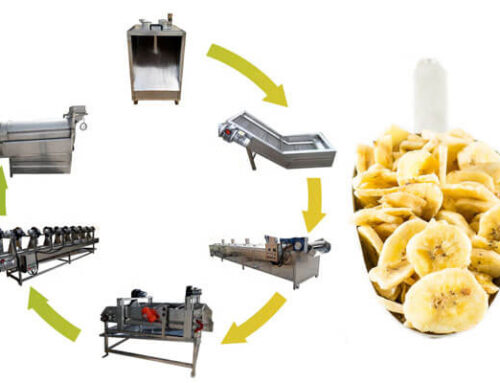

3) Apart from using potato as material, you could also use other food as well, such as sweet potato, banana, taros, apple, carrot and other kinds of taros.

4) The multipurpose cutting machine, able to cut potatoes to slice or bar shape, and you could adjust the thickness and size of them.

5) The advanced frying machine, highly increasing the using life of oil, saving energy.

6) Easy operation, high output, and good production effect.

Machines Equipped in Our Automatic Chips Making Plant

1. Elevator: used for transmitting large quantity of potatoes into the potato washing and peeling machine.

2. Potato washing and peeling machine: used to wash and peel potatoes automatically.

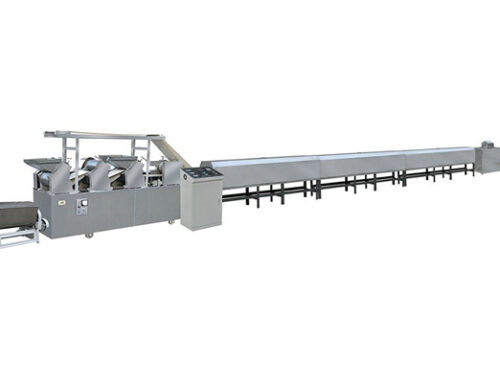

3. Potatoes picking line: picks the well-formed potatoes and sends them to cutting machine. The blades are stainless steel and specially designed to cut them averagely.

4. Blanching line: a necessary part in processing potato chips and other vegetables and fruits because the blanching process can protect their natural flavor from being broken.

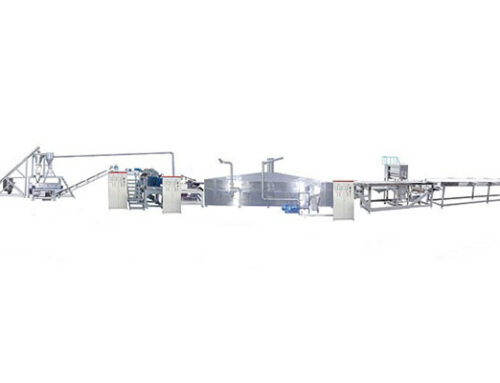

5. Potato electric heating frying line: an important step. The edible oil temperature should be around 180℃; when the potato chips become golden and soft, they should be fished out. Just grasp the right time, neither too early nor too late.

6. De-oiling line: make the fried food crispier and more palatable.

7. Flavoring line: customers can season diversified flavors totally according to their own intentions.

8. Packing line and automatic picking line: pack potato chips into bags automatically, very convenient, save your labor and ensure the quality.

A Glance of Potato Chips Flavors Around the World

A Glance of Potato Chips Flavors Around the World

1. In Britain, potato chips are called “crisps” (and they say “chips” when they mean fries!).

2. In Germany the most popular flavor is Paprika.

3. Indian chips are often exotic spices used in curries, like Masala, Coriander and Red Chili.

4. In Indonesia they make chips from Cassava.

5. In Greece, oregano is the most popular flavor.

6. Japanese chip-eaters enjoy Seaweed, Wasabi and Soy Sauce & Butter Chips!

Output of Automatic Potato Chips Manufacturing Plant We Can Offer

▷100-150 kg/h, 200-260 kg/h, 350-400 kg/h

▷We could customize the potato chips production line according to your own requirements.

Automatic Potato Chips Production Line Technical Data

|

No.

|

Name

|

Power/Voltage

|

Dimension

|

|

1

|

Elevator

|

0.55 kW/380V/50Hz

|

2535*900*2150 mm

|

|

2

|

Washing and Peeling Machine

|

2.75 kW/380V/50Hz

|

3050*800*1600 mm

|

|

3

|

Potato Picking Line

|

0.55 kW/380V/50Hz

|

3700*1040*940 mm

|

|

4

|

Elevator

|

0.55 kW/380V/50Hz

|

1700*700*1740 mm

|

|

5

|

Potato Cutting Machine

|

1.5 kW/380V/50Hz

|

670*510*1400 mm

|

|

6

|

Bubble Cleaning Line

|

1.87 kW/380V/50Hz

|

3490*1450*1400 mm

|

|

7

|

Blanching Line

|

40.5 kW/380V/50Hz

|

5100*1070*1240 mm

|

|

8

|

Rinsing Line

|

1.87 kW/380V/50Hz

|

3490*1450*1400 mm

|

|

9

|

Air-cooled De-watering Machine

|

6 kW/380V/50Hz

|

4100*850*1840 mm

|

|

10

|

Electrical Frying Line

|

125 kW/380V/50Hz

|

5600*1700*2250 mm

|

|

11

|

De-oiling Line

|

6 kW/380V/50Hz

|

4100*850*1880 mm

|

|

12

|

Flavoring Line

|

1.12 kW/380V/50Hz

|

3240*850*2200 mm

|

|

13

|

Picking Line

|

0.55 kW/380V/50Hz

|

3560*700*1255 mm

|

|

14

|

Packing Machine

|

6 kW/380V/50Hz

|

/

|

A Glance of Potato Chips Flavors Around the World

A Glance of Potato Chips Flavors Around the World