Introduction of Bubble Gum Forming Production Line

ALC6-300II odd-shape bubble gum forming production line is suitable for forming various shapes of toffee, mild candy, hard candy and bubble gum with high capacity. This whole production line is an integrated automatic production line that can make sweets like a ball shape, strawberry shape, oval shape, cylinder shape with hollow, sandwich or jam inside. It can be customized according to the customer’s request.

Main Performance of Bubble Gum Forming Production Line

Main Performance of Bubble Gum Forming Production Line

1. Adopt unequal space screw pressing technology(no equidistant twin-screw extrusion technology), make the gum base free group even and chewing gum good taste.

2. Adopt frequency conversion control technology, make the machine work stable.

3. Adopt differential speed working principle, make bubble gum balls tasty and beautiful..

4. One production line can be equipped with 6 sets of forming machines and 6 sets of sugar coating machines.

Features of Bubble Gum Forming Production Line

1. Adopts the integration process of forming, cutting, packaging process, clear function, and organic combination, plan as a whole operation, can reach the assembly line process.

2. Mainframe with SS304 cover, material contacting parts uses food grade material.

3. The agitator is equipped with a lid. Shutdown protection: there is a timing protection (adopt time relay), manual operation stop protection, have open cover protection.

4. Equipped with Industrial dehumidifier-5HP high-temperature constant temperature refrigeration dehumidifier, anti-corrosion and can accurately control the baking temperature, uninterrupted baking.

5. The passageway of cooling convey cabinet under cold wind effect to achieve cooling and dehumidification purpose, also can preserve moisture and heat preservation the candy stick.

6. Can be equipped with Sandwich Pump to fill sandwich or jam inside the candy.

7. Can be equipped with an automatic packaging machine, adopts high-quality electrical components, PLC control, packing speed adopts frequency conversion stepless speed adjustment

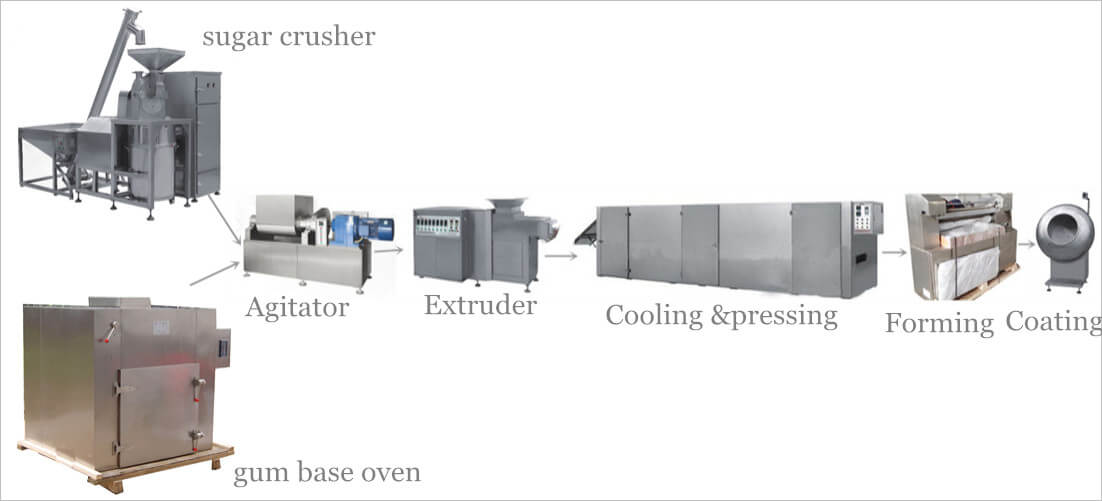

Product Process of Bubble Gum Forming Production Line

| Sugar crusher Gum base oven |

>Agitator→ Extruder→ Cooling and pressing→ Forming→ Coating |

Main Technical Parameters of Bubble Gum Forming Production Line

| Production Speech | 300-600kg/h |

| Pellet Forming Diameter | 10-25mm |

| Dimension | 15000*4000*1500mm |

| Gross Power | 84kw |

| Power Supply | 380v |

| Gross Weight | 8850kg |

Technical Parameters for Each Bubble Gum Forming Production Line Machine

| Name | Power | Dimension | Weight |

| Agitator | 20kw | 2300*890*1400mm | 1500kg |

| Extruder | 20kw | 2500*1180*1550mm | 2200kg |

| Cooling Conveyor | 18kw | 9500*1850*1800mm | 2500kg |

| Forming Machine | 2.2kw | 1500*700*1500mm | 400kg |

| Coating Machine | 2.2kw | 1600*730*1450mm | 350kg |

| Sandwich Pump | 2.5kw | 1600*500*1050mm | 300kg |

Kindly Reminder

Please let us know the follow packing details when you offer so that we can check if this model is suitable for your case. Thank you in advance.

1. Product details, what kinds of packing do you want? (a photo will be helpful to us)

2. How about your power? Voltage/Frequency

3. What capacity do you want?