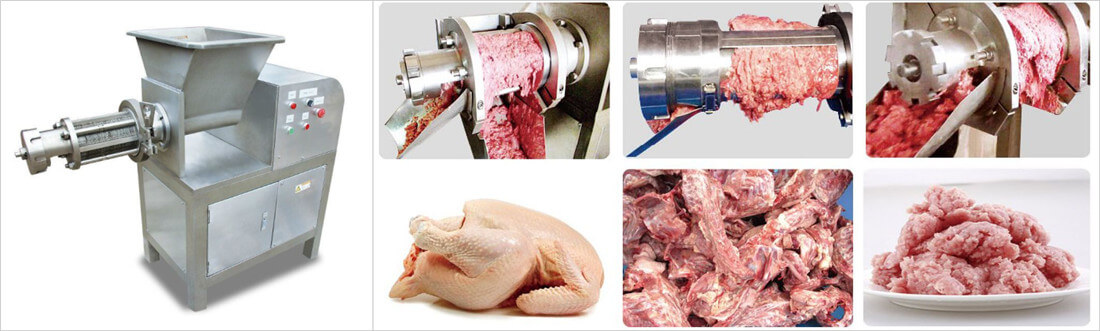

Poultry Deboning Machine Introduction

Poultry deboning machine is ideal equipment used for deboning the poultry, rabbit carcass or small animal skeleton, and produce meat paste in order to further process them into meat products efficiently. Our poultry deboner machine adopts with imported high-quality motor and can grind the meat to make it easy for other food processing, such as sausage, meatball, and dumpling, etc. The ground meat can maintain its original various nutrients and good freshness. It is used in meat processing factory, frozen food processing factory, hotel, restaurant and so on.

Poultry Deboning Machine Features

◇All material of high-quality stainless steel and high hardness alloy knife., anti-corrosion and waterproof.

◇Can apply to all poultry products processing, no need to pre-split.

◇The machine has a compact structure, stable operation, large output, simple to operate, convenient to clean and maintenance

◇During the whole separation process, it is no need to ask people to operate, which makes it convenient and Hygeian.

◇The degree of pressure between the rubber belt and the adopting tube is regulated by a slack adjuster of rubber belt located in the head of the machine.

◇The adjustment range can be changed flexibly according to the size of fish.

Bone Grinding Machine Working Principle

With mechanical grading, the meat with bone is ground, screened and then separated. the characters of the meat and bone are different, so the meat can be screened through the filter screen.

Application of Poultry Deboning Machine

This deboning machine is widely used in making sausage, meatball, spice and condiment making area, food ingredients, bone soup, bone glue, bone meal, and other industries to debone the chicken bones, cow bones, fish bones, sheep bones, pig bones, horse bones, and various other animal or poultry bones.

|

|

|

Poultry Deboning Machine Technical Parameters

| Model | ALGF-200 | ALGF-600 |

| Capacity | 160-260 kg/h | 1300-2300 kg/h |

| Power | 4kw | 21 kw |

| Dimensions | 1440*760*910mm | 2390*1200*2100 mm |

| Weight | 400 kg | / |

Meat Output Rate of the Raw Material

| Raw material | Meat output rate |

| Chicken meat bone | 75% |

| Chicken Meat | 90% |

| Chicken leg meat bone | 42% |

| Chicken meat necks | 80% |

| Rabbit skeleton | 50% |

How to Operate Bone Grinding Machine

☆Check the cage is installed in place.

☆Adjust the screw pressure according to the different situation of the materials.

☆Check there is nothing embedded or stuck in the hopper, a safety switch is reset.

☆When the machine stops, the operator should remove the stirring cage orifice, the regulating nut should be put down gently in order to avoid the clash.

☆Fill cooking oil to the grinding head hole regularly.